SHENZHEN, China, April 21, 2025 /PRNewswire/ — Energy storage has garnered unprecedented attention regarding its safety and reliability. On January 16, 2025, a fire broke out at the Moss Landing lithium battery energy storage power plant in California, USA. This is not the first accident at the Moss Landing energy storage plant. In both 2021 and 2022, the plant experienced fires caused by overheating due to unexpected moisture exposure of the batteries. The specific cause of this latest incident is still under further investigation.

In recent years, many countries around the world have been deploying large-scale lithium battery energy storage facilities. However, safety concerns have become a “Sword of Damocles” hanging over the energy storage industry. Risks such as internal short circuits, overcharging, over-discharging, external environmental temperature impacts, misuse, and battery management system failures can lead to thermal runaway in battery cells, potentially causing fires.

TS-800: An Upgrading for the Way in Fire Safety Test

In 2024, the internationally renowned certification body CSA issued TS-800, a large-scale fire test protocol for energy storage systems. This test provides manufacturers with direct criteria for optimizing system safety, while also offering critical data for regulatory agencies, fire departments, and insurance companies to assess risks.

The advancement of site-level energy density is a crucial driving indicator for industry development. With active fire suppression systems turned off, the challenge lies in arranging units more densely while ensuring that thermal runaway in one unit does not affect others. This metric profoundly challenges the boundaries of energy storage fire safety design.

“The existing standards (such as UL 9540A) are capable of testing for thermal runaway, but they do not adequately simulate fire propagation scenarios, especially in multi-module container systems where a single battery fire can potentially ignite adjacent units or even the entire system. The core goal of the TS-800 test is to address this gap,” said Marvin Peng, the Battery & Energy Storage Certifier of CSA Group.

The Aqua-C2.5 is world’s first large-scale energy storage system to adopt an active ventilation fire protection design

In 2024, Sungrow verified that its liquid-cooled energy storage system endured four hours of combustion laid in an A/B array. All cabinets remain unharmed and without any fire spreading to its surroundings and the structure remained intact, the battery compartment doors did not open, and no mechanical parts were ejected. That because Sungrow applied pressure-sensing explosion venting, multi-layer fire resistance, and dual-compartment design in its PowerTitan system, which played a crucial role in ensuring the safety of the entire energy storage system. Moreover, Sungrow Power further announced that its next-generation large-scale storage product, PowerTitan 2.0, had also passed the large-scale fire test. Additionally, leading energy storage companies Trina Storage and BYD claimed to have passed the large-scale fire test in October 2024 and January 2025, respectively.

Challenge the Limit Spacing: A Breakthrough in Energy Storage Safety

Recently, the 15 years pioneers of energy storage commercialization——CLOU Electronics has announced completing the CSA TS-800 Large-Scale Fire Test (LSFT) in February 2025. This achievement again highlights its unwavering commitment to developing innovative, reliable, and safe energy storage solutions for a global market.

“CLOU committees that every product delivered is trustworthy and has undergone rigorous testing. The Aqua-C2.5 5MWh utility scaled energy storage system is the world’s first large-scale energy storage system to adopt an active ventilation fire protection design. Through active cell sensing, it triggers an electric shutter explosion suppression solution in thermal runaway scenarios, effectively controlling the spread of thermal runaway at extreme short distances in 140mm,” said Eric Wang, System Director of CLOU ESS Division.

The Aqua-C2.5 was lunched at September 2024, it also engineered for durability with an impressive C5 anti-corrosion rating and IP55 protection. It has earned multiple certifications, including CE, UL1973, UL9540A, UL9540, IEC62619, IEC63056, IEC62477-1, UN38.3, NFPA855, and NEC, and has passed the rigorous IEEE693 seismic test.

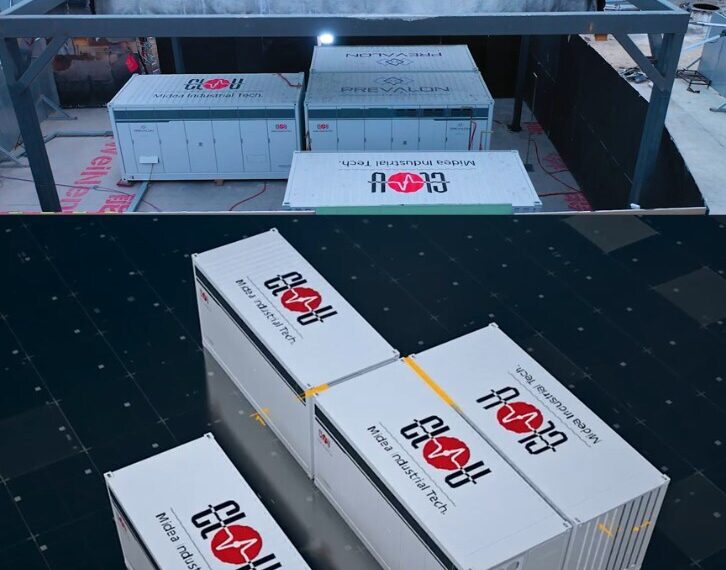

CLOU Aqua-c2.5 20ft cabinets were arranged according to an actual A/B A/D back-to-back and side to side real station layout. All cabinets were spaced in an extreme short distance apart with full load capacity to replicate operational scenarios

The experiment adhered to stringent technical specifications throughout the testing process. Under the supervision of the CSA Group, the TS-800 LSFT subjected the product to extreme fire conditions, simulating a real-project conditions, four 20ft cabinets were arranged according to an actual A/B A/D back-to-back and side to side real station layout. All cabinets were spaced in an extreme short distance apart with full load capacity to replicate operational scenarios. The test also aims to evaluate whether the structural design (such as fire barriers) and material selection (such as flame-retardant components) can effectively prevent the spread of fire when external firefighting measures completely fail.

During the test, temperatures inside the battery cabinet exceeded 1000°C and burned consistently for 48 hours. Despite this, the adjacent cabinets’ temperatures remained below 40°C since the product’s active ventilation blade employing function like active detection and off-gassing, which maximally prevent combustion and ensure thermal isolation.

“The results were remarkable: the Aqua-C2.5 demonstrated excellent flame retardancy, thermal insulation, and superior safety design.” Battery & Energy Storage Certifier of CSA Group Marvin Peng said. Meanwhile, after the combustion test, the structural integrity fully preserved, also showcasing the exceptional rigidity and compressive performance of its design, redefining the durability and stability of energy storage products. This milestone underscores the system’s ability to safeguard against fire risks in even the harshest conditions, setting a new safety benchmark in the energy storage industry.